Effective and excellent PCB assembly is fundamental for the fruitful creation of electronic gadgets. From model advancement to large scale manufacturing, streamlining the pcb assembly process can prompt expense investment funds, quicker time-to-advertise, and further developed item dependability.

- Plan for Manufacturability (DFM)

The most important phase in streamlining the PCB assembly process is to plan for manufacturability (DFM). This includes planning the PCB design in view of assembly and assembling contemplations, for example, part position, follow directing, and solderability. By enhancing the plan for simplicity of assembly, you can lessen the probability of blunders, limit revamp, and further develop generally creation efficiency.

- Part The executives and Obtaining

Productive part the board and obtaining are basic for guaranteeing a smooth PCB assembly process. Keeping a coordinated stock of parts, including both dynamic and uninvolved parts, forestalls deferrals and deficiencies. Also, joining forces with solid providers and executing in the nick of time (JIT) stock administration practices can smooth out the acquirement process and limit lead times.

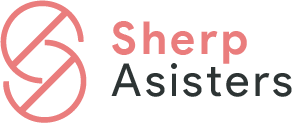

- Mechanized Assembly Hardware

Putting resources into mechanized assembly hardware, for example, pick-and-spot machines, patch glue printers, and reflow stoves, can altogether work on the efficiency and exactness of PCB assembly. Robotized gear decreases physical work, speeds up creation cycles, and guarantees predictable quality across clusters.

- Lean Assembling Standards

Applying lean assembling standards, like nonstop improvement and waste decrease, can additionally streamline the pcb assemblyprocess. Procedures, for example, esteem stream planning, kaizen occasions, and 5S approach assist with recognizing shortcomings, dispose of non-esteem added exercises, and smooth out work process processes. By cultivating a culture of consistent improvement, associations can upgrade efficiency, decrease expenses, and improve item quality.

- Quality Control and Testing

Quality control and testing are critical stages in guaranteeing the dependability and performance of collected PCBs. Executing thorough quality control measures, like in-process reviews, utilitarian testing, and dependability testing, distinguishes and amend surrenders right off the bat in the creation process.

Streamlining the PCB assembly process requires a mix of vital preparation, productive asset the executives, and ceaseless improvement drives. By taking on best practices like plan for manufacturability, successful part the executives, mechanized assembly gear, lean assembling standards, and strong quality control measures, associations can accomplish more prominent efficiency and quality in PCB assembly. By upgrading the assembly process, organizations can lessen costs, speed up chance to-showcase, and convey great electronic items that meet client assumptions.